What is CNC Machining?

While CNC machining is not an everyday term, it is an essential part of modern life because it creates components for the technology we use daily.

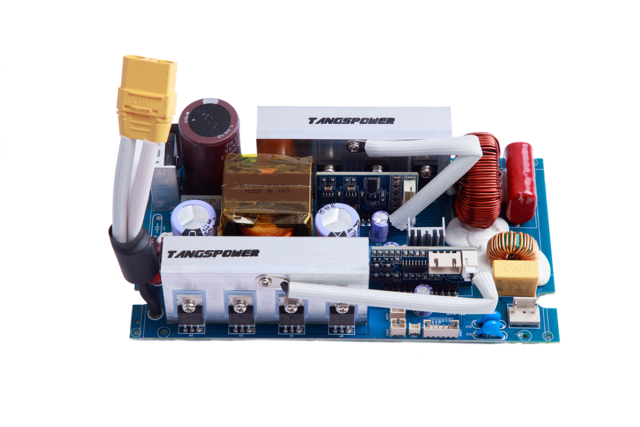

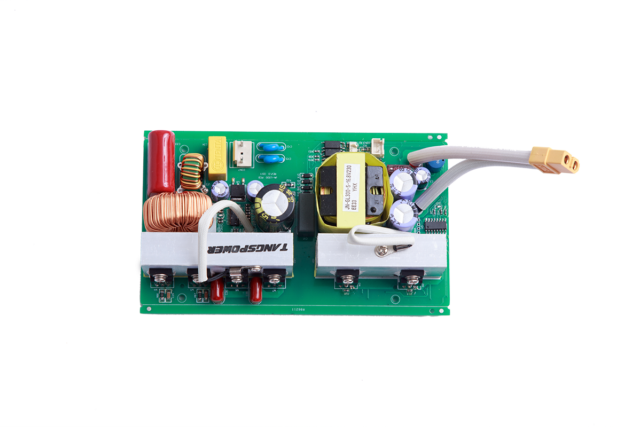

According to experienced CNC machining specialist Elite CNC, once instructions are inputted into a computer program, CNC machines work tirelessly to cut and grind raw material into a finished part. The process creates vehicle gears, electrical circuit boards and even kitchen utensils. So, what exactly is it and how does it work? Let’s explore the processes that go into this fascinating technology.

How Does a CNC Machine Work?

CNC stands for Computer Numerical Control, describing the set of instructions programmed into a CNC machine. These instructions tell the machine when and where to cut and which tools to use. CNC machining uses a technique called ‘subtractive fabrication,’ where the machine removes material from a ‘blank,’ which could be a block, sheet, or another piece of material.

CNC machines need a set of digital computer instructions to work, so programmers follow a process to convert the initial design into code the machine can understand. Firstly, a designer uses Computer Aided Design software (CAD) to create a model of the part, including all dimensions. This contains the information needed, but it needs to be translated into a language the CNC machine can understand.

To do this, a programmer uses Computer Aided Manufacturing software (CAM), which converts the CAD model into a set of instructions that the machine can follow. The program provides coordinates to guide the tools alongside other important information such as cutting speed. In short, the code tells the machine what it should be doing and in what order.

CNC machines can use a number of processes, including milling, cutting, routing and drilling to remove material and leave the finished piece. With the CNC machine programmed, the operator can fix the blank material into the machine, ready for fabrication.

What is CNC Machining Used For?

CNC machining produces parts, components, and models for a wide range of industries. If you take a look around your home or workplace, many of the everyday items you see were manufactured by these machines.

CNC machining has the capability to produce diverse components, including airplane landing gears, alloy wheels, kitchen and barbeque tools, pipelines and so much more. At the other end of the scale, CNC provides us with intricate electronic components and medical implants. That’s why it is a popular choice in industries like aerospace, defence industrial machinery, infrastructure, electrical, mining, automotive, food and beverage and product design.

As a versatile process, CNC machining suits many different materials. Metals are common, including aluminium, stainless steel, brass, and even titanium, but CNC machines can also work with many types of plastic, wood, foams and other materials. Alongside the traditional lathes, drills, routers, and mills, technologies such as water jets and even plasma cutters mean that CNC machines complete most tasks.

As long as the right code is programmed, the CNC machine will carry out each step to precision because it is repeatable. Once you set the design, you have the flexibility to make as many copies as you want without any deviation in size, shape and finish.

What are the Benefits to Your Business?

For any business contemplating CNC machining, what are the benefits? There are certainly many good reasons why CNC makes sense. First is speed and efficiency because CNC machines follow their programs tirelessly and churn out multiple parts quickly. Just as importantly, they are precise, and every part is exactly the same. Finally, automation leaves less scope for human error, fewer accidents and, therefore, lower costs.

Another way in which CNC machining lowers costs is by reducing the labour needed, especially when compared to fabrication. While CNC designers and programmers need advanced skills, the machining process does not need skilled welders or fabricators, further decreasing costs and making CNC machining affordable. Lower production costs have made it viable for smaller businesses to use CNC machining and gain a far more competitive edge than ever before.

CNC machines have fine tolerances and can create complex designs easily. Because CNC machining is relatively easy to set up, it is particularly useful for making prototypes, taking them from design to production. It is relatively easy to test the component and make changes to the CAD model as needed.

Naturally, CNC machining is not always the best solution and your business may still need other techniques such as fabrication or 3D printing. For example, because the process is subtractive and removes material to leave the final part, this creates a lot of expensive waste, although better recycling is tackling this problem. Determining whether CNC machining is the right choice requires speaking to experts who know exactly what the technology can achieve.

What are the Skills Required to Operate CNC Machines?

While the machine does all the work to produce the final component, the operator must have sufficient technical skill and knowledge to program and manage such high-tech machinery.

Some important skills include being able to read blueprints, designs, CAD designs and CAM files. Operators should also know how to set up and program the machines, including fine-tuning the workpiece and cutting tools. In addition, operators will need to monitor the different processes to ensure the parts are being cut to specification. Finally, a quality check will ensure the product is tested for defects.

With so many advancements in technology today, the process is not as cumbersome or gritty as before. Operators today are highly skilled in this field and use these machines in a professional setting.

The Bottom Line

Overall, CNC machining has secured its place as a reliable and accurate way to produce parts for different industries. It is able to quickly and accurately deliver finished plastic or metal products by combining design, technical drawings and computer programming – lowering production costs and downtime for businesses.

But because CNC machining can be a complex process with many stages, it’s important to work with a specialist that understands the technology and your industry so they can deliver the quality finish and product you are looking for in your business.